In modern industrial manufacturing, heat treatment plays a crucial role in improving the mechanical properties, strength, and durability of metal components. Among various industrial furnace types, the Bogie Hearth Furnace stands out as a reliable and efficient solution for handling heavy, bulky, and large-sized components. Trymax, a leading manufacturer of all types of furnaces, delivers advanced bogie hearth furnace solutions designed to meet the demanding requirements of industries across India.

What Is a Bogie Hearth Furnace?

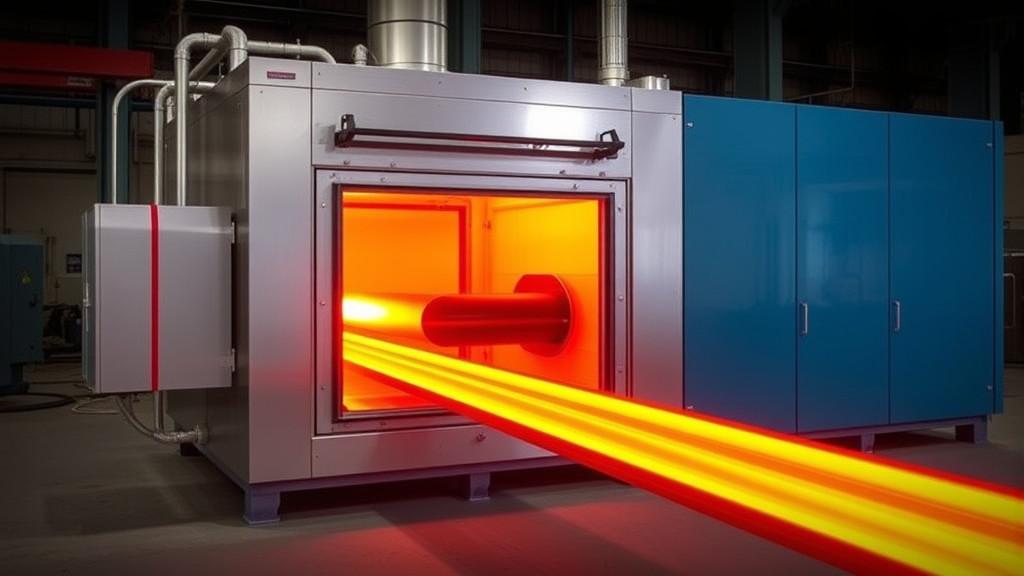

A Bogie Hearth Furnace is a type of industrial heat treatment furnace designed for processing heavy loads at high temperatures. It features a movable hearth (bogie) mounted on rails, which allows easy loading and unloading of large components such as castings, forgings, fabricated structures, and heavy machinery parts.

Unlike conventional stationary furnaces, a bogie hearth furnace provides excellent flexibility, making it ideal for industries that deal with oversized or high-weight components. These furnaces are commonly used for processes such as annealing, normalizing, stress relieving, tempering, and solution treatment.

Working Principle of a Bogie Hearth Furnace

The working principle of a bogie hearth furnace is simple yet highly effective. The metal components are placed on the bogie outside the furnace chamber. Once loaded, the bogie moves smoothly into the furnace along rails. After the door is securely closed, the heating cycle begins.

The furnace uses industrial burners or electric heating elements to raise the temperature according to the required heat treatment process. Uniform heat distribution is maintained through advanced combustion systems, airflow management, and high-quality refractory linings. After the soaking time is completed, the bogie is pulled out for controlled cooling or further processing.

Key Features of a Bogie Hearth Furnace

Trymax designs bogie hearth furnaces with a strong focus on performance, safety, and durability. Some of the key features include:

-

Heavy-duty bogie structure capable of handling high loads

-

Uniform temperature distribution throughout the furnace chamber

-

High-quality refractory insulation for minimal heat loss

-

Advanced industrial burner systems for fuel efficiency

-

Easy loading and unloading of large components

-

Custom-designed furnace dimensions based on client requirements

-

Reliable door sealing mechanisms to maintain thermal efficiency

These features ensure consistent performance and long operational life even under continuous industrial usage.

Applications of Bogie Hearth Furnace

The Bogie Hearth Furnace is widely used across multiple industries due to its versatility and ability to handle heavy components. Common applications include:

-

Heat treatment of heavy steel castings and forgings

-

Stress relieving of welded structures

-

Annealing of fabricated components

-

Normalizing and tempering of large machine parts

-

Heat treatment for automotive, aerospace, and railway components

-

Processing of power plant and heavy engineering equipment

Industries such as steel manufacturing, heavy engineering, automotive, defence, and infrastructure rely heavily on bogie hearth furnaces for consistent and controlled heat treatment.

Advantages of Using a Bogie Hearth Furnace

A bogie hearth furnace offers several advantages over conventional furnace systems:

1. Easy Material Handling

The movable bogie eliminates the need for complex material handling systems, making it easier to load and unload heavy components safely.

2. High Load Capacity

Bogie hearth furnaces are specifically designed to handle high-weight and large-size components without compromising performance.

3. Uniform Heating

Advanced furnace design ensures uniform temperature distribution, which is critical for achieving desired metallurgical properties.

4. Energy Efficiency

With proper insulation, industrial recuperators, and efficient burners, these furnaces reduce fuel consumption and operational costs.

5. Customization

Bogie hearth furnaces can be fully customized in terms of size, temperature range, heating method, and control systems.

Heating Methods Used in Bogie Hearth Furnace

Trymax manufactures bogie hearth furnaces using different heating methods based on customer needs:

-

Gas-fired bogie hearth furnace using natural gas, LPG, or furnace oil

-

Electric bogie hearth furnace for precise temperature control

-

Dual-fuel systems for operational flexibility

Each heating method is selected to match the application, production volume, and energy efficiency requirements.

Why Choose Trymax for Bogie Hearth Furnace?

Trymax is recognized as a leading manufacturer of industrial furnaces, offering end-to-end solutions from design and engineering to installation and commissioning. With extensive experience in furnace technology, Trymax delivers bogie hearth furnaces that meet international quality and safety standards.

Key reasons to choose Trymax include:

-

Expertise in all types of industrial furnaces

-

Custom-designed bogie hearth furnace solutions

-

High-quality materials and advanced manufacturing processes

-

Strong focus on energy efficiency and performance

-

Pan-India presence with reliable after-sales support

-

Proven track record across multiple industrial sectors

Trymax works closely with clients to understand their heat treatment requirements and deliver furnace systems that improve productivity and product quality.

Maintenance and Safety Considerations

Proper maintenance is essential for ensuring the long-term performance of a bogie hearth furnace. Regular inspection of burners, refractory linings, rails, and bogie wheels helps prevent downtime. Trymax designs furnaces with easy maintenance access and robust safety features such as temperature controllers, flame failure devices, and emergency shut-off systems.

Safety is a top priority, especially when handling high-temperature operations and heavy loads. A well-designed bogie hearth furnace minimizes operational risks while ensuring smooth and safe production cycles.

Future of Bogie Hearth Furnace Technology

With growing demand for energy-efficient and sustainable manufacturing, bogie hearth furnace technology continues to evolve. Integration of automation, digital temperature control systems, and energy recovery solutions such as industrial recuperators is becoming increasingly common. Trymax remains committed to adopting advanced technologies that enhance furnace efficiency and reduce environmental impact.

Conclusion

The Bogie Hearth Furnace is an essential solution for industries requiring reliable heat treatment of heavy and large components. Its flexibility, high load capacity, and uniform heating make it a preferred choice for modern manufacturing. As a leader in all types of furnaces, Trymax delivers robust, efficient, and customized bogie hearth furnace solutions across India. By choosing Trymax, industries can ensure superior heat treatment performance, operational efficiency, and long-term reliability.