Hydrated lime plays a crucial role in modern infrastructure and environmental management. From strengthening building materials to purifying drinking water, this versatile compound has become an essential component across multiple industries. Choosing the right Hydrated Lime Manufacturers is critical to ensure consistent quality, safety, and performance in both construction and water treatment applications.

What is Hydrated Lime?

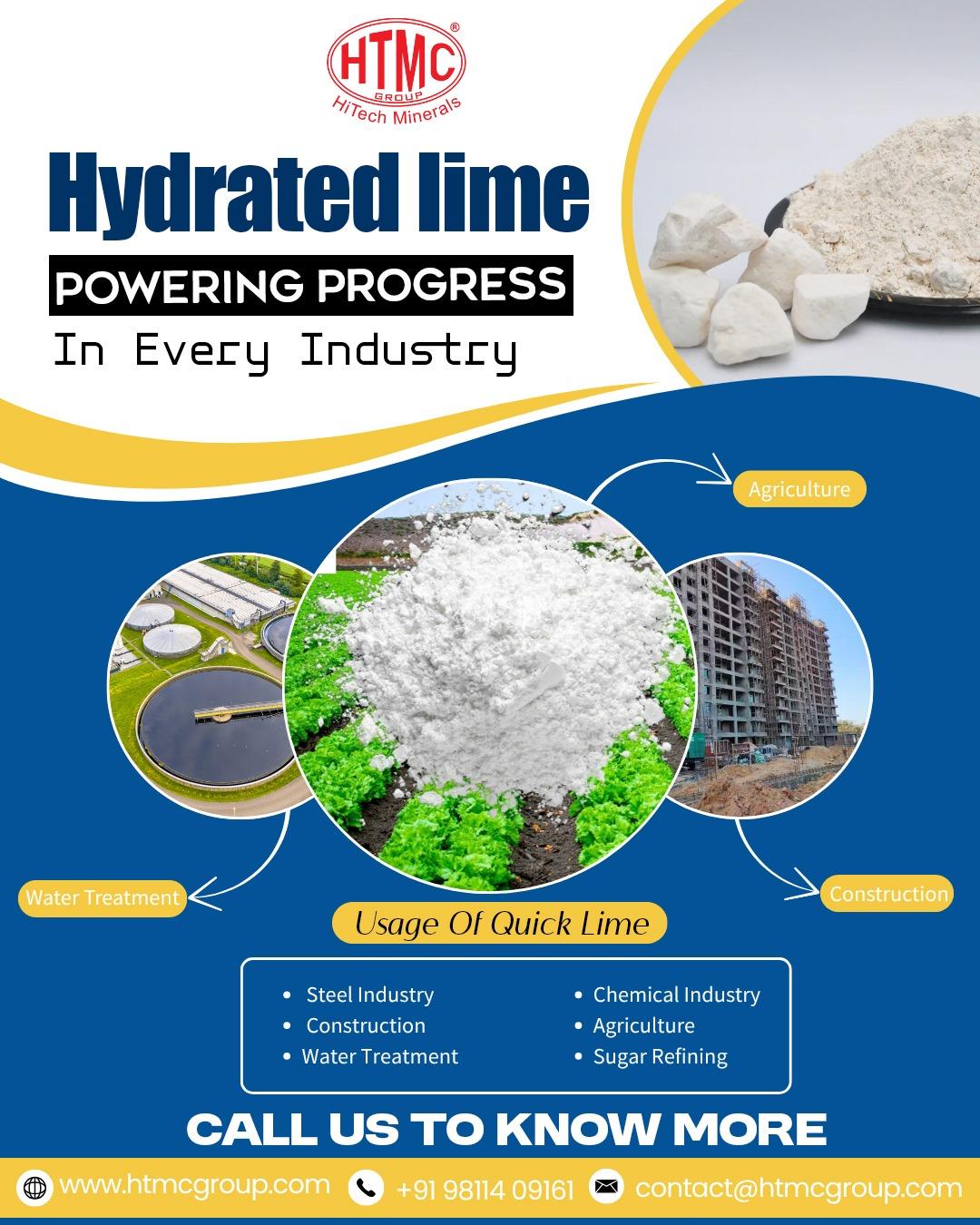

Hydrated lime, also known as calcium hydroxide, is produced by adding water to quicklime (calcium oxide). This process creates a fine, dry powder that is easy to handle and highly effective in chemical reactions. Due to its alkaline properties, hydrated lime is widely used in construction, wastewater treatment, soil stabilization, and various industrial processes.

Reliable Hydrated Lime Manufacturers follow strict quality standards to ensure the product has high purity, controlled particle size, and minimal impurities.

Importance of Hydrated Lime in Construction

The construction industry depends heavily on hydrated lime for improving the strength, durability, and workability of materials. Here are some of its primary applications:

- Soil Stabilization

Hydrated lime is commonly used to stabilize clayey and weak soils. It reduces plasticity, increases load-bearing capacity, and improves long-term durability. Road construction projects, highways, and foundation works often rely on lime-treated soil for better performance.

- Mortar and Plaster

In masonry work, hydrated lime enhances the flexibility and bonding strength of mortar. It improves water retention, making the mixture easier to apply while reducing cracks. Many experienced contractors prefer materials sourced from trusted Hydrated Lime Manufacturers to ensure consistent results.

- Asphalt Modification

Hydrated lime is also used as an additive in asphalt mixtures. It increases resistance to moisture damage and improves pavement longevity. This makes it especially valuable in regions with extreme weather conditions.

- Environmental Protection in Construction

Lime helps control harmful emissions and stabilizes hazardous waste materials, ensuring compliance with environmental regulations.

Role of Hydrated Lime in Water Treatment

Water treatment plants use hydrated lime extensively due to its strong alkaline properties. Its ability to neutralize acids and remove impurities makes it highly effective in both municipal and industrial water systems.

- pH Adjustment

Hydrated lime helps maintain optimal pH levels in water. Proper pH control is essential for safe drinking water and efficient treatment processes.

- Removal of Heavy Metals

It assists in precipitating heavy metals such as iron, manganese, and other contaminants. This improves water clarity and safety.

- Softening Hard Water

Lime treatment reduces hardness by removing calcium and magnesium ions, making water suitable for domestic and industrial use.

- Wastewater Treatment

Industrial wastewater often contains acidic compounds and harmful pollutants. Reputed Hydrated Lime Manufacturers supply high-quality material that ensures effective neutralization and sludge stabilization.

Key Qualities of the Best Hydrated Lime Manufacturers

Selecting the right supplier is crucial for achieving the desired performance in construction and water treatment projects. Here are some essential factors to consider:

- High Purity Levels

Premium manufacturers ensure high calcium hydroxide content with minimal impurities. Purity directly affects performance and efficiency.

- Advanced Manufacturing Process

Modern production facilities use controlled hydration processes and advanced machinery to maintain uniform particle size and consistent quality.

- Quality Certifications

Top manufacturers comply with industry standards and provide proper quality certifications. This guarantees product reliability and regulatory compliance.

- Bulk Supply Capability

Large-scale projects require uninterrupted supply. Established Hydrated Lime Manufacturers maintain strong logistics networks to ensure timely delivery.

- Custom Packaging Options

From bulk tankers to small bags, flexible packaging solutions make handling and storage easier for different industries.

Benefits of Choosing Reliable Hydrated Lime Manufacturers

Partnering with experienced manufacturers offers several advantages:

- Consistent product quality

- Competitive pricing

- Technical support and guidance

- On-time delivery

- Environmentally responsible production

Reliable suppliers understand the specific requirements of construction firms and water treatment facilities, ensuring the product meets project demands without compromise.

Growing Demand for Hydrated Lime in India

With rapid urbanization and infrastructure development, the demand for hydrated lime continues to rise. Large-scale road projects, smart cities, wastewater treatment plants, and industrial growth contribute significantly to market expansion.

Leading Hydrated Lime Manufacturers are investing in advanced technology and sustainable production methods to meet this growing demand while minimizing environmental impact.

How to Choose the Right Manufacturer

Before finalizing a supplier, consider the following steps:

- Check product specifications and test reports.

- Evaluate production capacity and delivery timelines.

- Compare pricing without compromising on quality.

- Review customer testimonials and industry reputation.

- Ensure compliance with environmental and safety standards.

Taking these measures ensures you select a manufacturer capable of delivering reliable and high-performance hydrated lime.

Conclusion

Hydrated lime remains a vital material for construction and water treatment industries. Its ability to strengthen infrastructure, stabilize soil, purify water, and protect the environment makes it indispensable. However, the effectiveness of hydrated lime largely depends on its quality.

Choosing trusted Hydrated Lime Manufacturers ensures superior purity, consistent performance, and dependable supply. Whether you are managing a construction project or operating a water treatment facility, partnering with an experienced manufacturer can significantly impact efficiency and long-term success.